Get sustainable processes for regenerated MMA

Introduction

Regenerated Methyl Methacrylate (MMA) is revolutionizing industries with its eco-friendly and sustainable approach to chemical reuse. As industries focus on reducing waste and improving sustainability, the regeneration of MMA plays a pivotal role in achieving these goals. This blog delves into the sustainable processes, industrial applications, and benefits of regenerated MMA, highlighting why it is a vital component for modern industry.

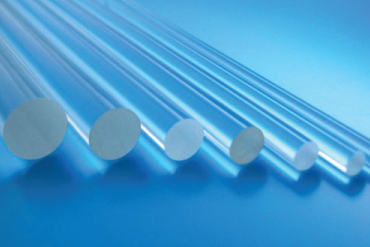

What is Regenerated MMA?

Regenerated MMA refers to Methyl Methacrylate recovered from post-industrial or post-consumer polymethyl methacrylate (PMMA) waste. This process involves breaking down PMMA into its monomeric form, allowing it to be reused in various applications.

Eco-Friendly Advantage: Reduces waste, lowers carbon footprint.

Cost Efficiency: Offers an economical alternative to virgin MMA.

Industrial Versatility: Ideal for applications in construction, automotive, and consumer goods.

Sustainable MMA Regeneration Processes

1. Depolymerization

This is the most common process, wherein PMMA is heated under controlled conditions to break it down into MMA monomers.

Key Benefits: High purity MMA, minimal waste.

Applications: Widely used in recycled plastics and coatings.

2. Solvent-Based Regeneration

In this method, solvents are used to dissolve PMMA, allowing the MMA to be extracted and purified.

Advantages: Reduced energy consumption, high yield.

Challenges: Requires careful handling of solvents to prevent environmental harm.

3. Catalytic Regeneration

Utilizes specific catalysts to speed up the depolymerization process.

Highlight: Faster process with lower energy requirements.

Eco-Benefit: Reduces emissions compared to conventional methods.

Applications of Recycled MMA in Industrial Use

Regenerated MMA serves a wide range of industries due to its high quality and versatility.

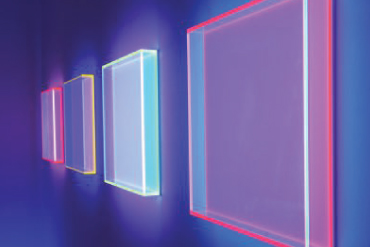

1. Construction Industry

Used in manufacturing acrylic sheets for windows, signage, and skylights.

Enhances durability and sustainability of building materials.

Contributes to green building initiatives.

2. Automotive Industry

Essential for creating lightweight and durable automotive parts.

Contributes to fuel efficiency and reduced emissions.

Helps manufacturers meet sustainability regulations.

3. Consumer Goods

Found in everyday items like electronics, furniture, and household products.

Provides aesthetic appeal with eco-friendly benefits.

Widely used in innovative packaging solutions.

4. Medical Devices

Used in the production of medical-grade materials like syringes and surgical instruments.

Ensures sterility and safety while maintaining sustainability.

Why Choose High-Quality MMA Regeneration Techniques?

Investing in high-quality regeneration techniques ensures:

Purity: Reduces impurities for superior performance.

Sustainability: Aligns with global environmental goals.

Cost-Effectiveness: Cuts costs in production and material procurement.

Innovation: Encourages the development of new products using recycled materials.

Top Suppliers and Manufacturers of Regenerated MMA

When sourcing regenerated MMA, consider trusted suppliers and manufacturers who prioritize quality and sustainability. Look for companies that:

Have certified processes for MMA regeneration.

Offer customizable solutions for various industries.

Maintain transparent supply chains.

Challenges in Regenerated MMA Adoption

Despite its advantages, regenerated MMA faces certain challenges:

Limited Awareness: Many industries are still unaware of its benefits.

High Initial Investment: Advanced regeneration technologies can be costly to implement.

Regulatory Barriers: Compliance with stringent environmental regulations requires additional resources.

However, as awareness grows and technology advances, these challenges are becoming easier to overcome.

Conclusion

Regenerated MMA represents a significant step towards sustainable industrial practices. By adopting regenerated MMA, industries can achieve environmental and economic benefits while meeting their operational needs. Sustainable MMA regeneration processes not only reduce waste but also pave the way for innovative applications across sectors.

Embrace the future of sustainable materials by choosing regenerated MMA—an eco-friendly solution for a better tomorrow. Whether in construction, automotive, or consumer goods, regenerated MMA is shaping a greener and more cost-efficient future.

Frequently Asked Questions

Here are the frequently asked questions (FAQs) that provide essential information about MMA Chemicals and our Methyl Methacrylate (MMA) Monomer products. These FAQs are designed to address common inquiries and help you understand why MMA Chemicals is the preferred choice for MMA Monomer.

Regenerated MMA is widely used in construction, automotive parts, consumer goods, and medical devices due to its durability and versatility.

Regenerated MMA is derived from recycled materials, making it more sustainable and cost-effective than virgin MMA, which is produced from raw resources.

Yes, with advanced regeneration techniques, the quality of regenerated MMA can match or even exceed that of virgin MMA.